New in Our Standard Product Range

Typical fields of application are food and pharmaceutical industries as well as general mechanical engineering with compressors and mobile units.

The V i b E x G a u g e is recommended wherever operating conditions exceed the requirements of the basic standard.

- Silicone-damped movement

- Break- and shatterproof glass (SAFETY GLASS)

- Wetted parts stainless steel 316L

- Restrictor screw Ø 0.01 / 0.02" in the pressure inlet port

- Optional: welded construction type (connecting piece welded with case)

- Safety case

For this purpose, the L u m e n G a u g e is equipped with a luminescent dial, a reflective pointer tip and two adjustable reflective marks. When illuminated with a flashlight, the position of the pointer between the marks can be seen even at greater distances.

When charged with a flashlight, with ambient light or daylight, the dial will glow in the dark for a certain period of time. This glow effect is beneficial in safety-relevant and critical areas of a process plant allowing technicians to monitor the operating pressure while carrying out their maintenance tasks.

- Luminescent dial

- Black pointer with silver reflecting coating

- Green reflecting marks

With its luminous yellow color, the measuring device quickly catches the eye in the installation. It also provides a higher contrast for easy reading. If the dial is illuminated with a lamp due to insufficient lighting, it is more visible than a white dial.

The B r i g h t D i a l can also be used to distinguish between different process lines or to highlight measuring points of greater importance.

- Dial luminous yellow

Available Devices

- Pressure gauges

- Thermometers

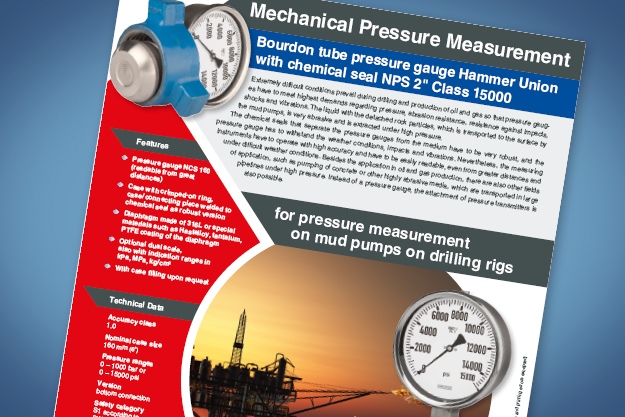

The chemical seals that separate the pressure gauges from the medium have to be very robust, and the pressure gauge has to withstand the weather conditions, impacts and vibrations. Nevertheless, the measuring instruments have to operate with high accuracy and have to be easily readable, even from greater distances and under difficult weather conditions.

Besides the application in oil and gas production, there are also other fields of application, such as pumping of concrete or other highly abrasive media, which are transported in large pipelines under high pressure. Instead of a pressure gauge, the attachment of pressure transmitters is also possible.

- Accuracy class 1.0

- Nominal case size 160 mm (6")

- Pressure ranges 0 – 1000 bar or 0 – 15000 psi

- Version bottom connection

- Safety category S1 according to DIN EN 837-1

- Permissible ambient temperature −40 °C to +60 °C (−40 °F to +140 °F)

- Chemical seal and process connection stainless steel 316L

- Diaphragm stainless steel 316L, flush welded

- Process connection NPS 2" Class 15000

- Pressure gauge NCS 160 (readable from great distances)

- Case with crimped-on ring, case / connecting piece welded to chemical seal as robust version

- Diaphragm made of 316L or special materials such as Hastelloy, tantalum, PTFE coating of the diaphragm

- Optional dual scale, also with pressure ranges in kPa, MPa, kg/cm²

- With case filling upon request

How about a thermometer with individual design?

Supplementing our industrial ambient thermometers, the TRCh 100 is now also available for private use.

The instrument with high-quality stainless steel case is weatherproof and reliably indicates the temperature both indoors and outdoors. Using the latest technology, we are able to design your customised thermometer. We can implement individual dials with your colour requirements, also combined with your text elements.

- Measuring system with nitrogen filling

- Accuracy class 1 (±0.8 °C)

- Case made of stainless steel

- Nominal case size Ø 100 mm (4")

- Temperature ranges

- −40 / +40 °C (−40 / +104 °F)

- −30 / +50 °C (−22 / +122 °F)

- −20 / +60 °C (−4 / +140 °F)

- Mounting back flange for wall mounting

We have developed a new process – the KCT process – with which we are able to apply PTFE foil in a very thin, homogeneous layer. The process has no effect on the operating capacity of the chemical seal. Thanks to this new process, even difficult shapes (e.g. clamp chemical seals) can be coated with foil.

- High chemical resistance (even with aggressive acids such as aqua regia)

- Excellent anti-adhesive properties (extremely low surface tension)

- Very good abrasion protection

- Very good sliding properties

- Physiologically safe

- High temperature resistance from −40 °C to +260 °C (−40 °F to +500 °F)

(please regard possible limitations due to the filling liquid) - Applicable up to 400 bar (5000 psi)

- Highly vacuum-proof up to 260 °C (500 °F) – depending on the filling liquid

- PTFE foils up to 0.5 mm (0.02") can be processed, with negligible influence on the measurement result

- Difficult shapes can be coated with foil (e.g. clamp chemical seals)

- Chemical seals made of special materials (e.g. tantalum) can be coated with foil

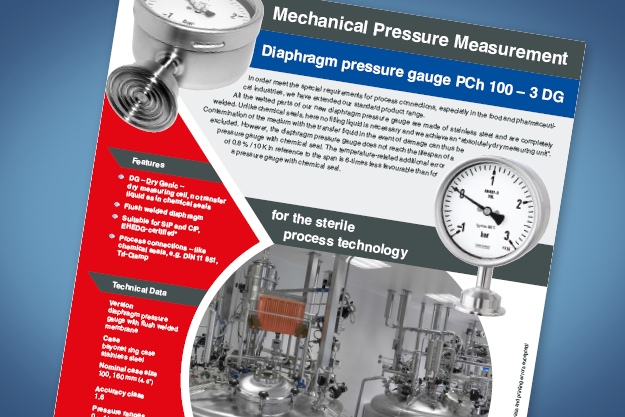

All the wetted parts of our new diaphragm pressure gauge are made of stainless steel and are completely welded. Unlike chemical seals, here no filling liquid is necessary and we achieve an “absolutely dry measuring unit”. Contamination of the medium with the transfer liquid in the event of damage can thus be excluded. However, the diaphragm pressure gauge does not reach the lifespan of a pressure gauge with chemical seal. The temperature-related additional error of 0.8 % / 10 K in reference to the span is 6-times less favourable than for a pressure gauge with chemical seal.

- Diaphragm pressure gauge with flush welded membrane

- Bayonet ring case stainless steel

- Nominal case size 100, 160 mm (4, 6")

- Accuracy class 1.6

- Pressure ranges 0 – 4 bar to 0 – 10 bar, also corresponding compound ranges

- Overpressure 1.3 times full scale value

- Permissible temperature

- ambience −20 °C to + 60 °C (−4 °F to +140 °F)

- medium −20 °C to +150 °C (−4 °F to +302 °F)

- Data sheet 3202

- DG – Dry Genic – dry measuring cell, no transfer liquid as in chemical seals

- Flush welded diaphragm

- Suitable for SIP and CIP, EHEDG-certified*

- Process connections – like chemical seals, e.g. DIN 11 851, Tri-Clamp

* For clamp connections and process connections according to DIN 11 851, an EHEDG approval for the sealing is required.

Pressure ranges: from 0 – 250 mbar to 0 – 40 bar

Overpressure: up to 5 times, max. 600 bar

There are measuring points at which extremely high overpressures do occur. For this purpose, our new diaphragm pressure gauge PCh 100 – 3 HOP is applicable. Depending on the pressure range, the instruments can withstand overpressures from 100 to 600 bar.

The specific requirements have to be coordinated with our solution possibilities. Options, which are available for “regular” diaphragm pressure gauges, are basically also possible here. Details also have to be specified, e.g. open connection flange, limit switch contact assembly.

- Diaphragm pressure gauge

- Bayonet ring case stainless steel

- Nominal case size 100, 160 mm (4, 6")

- Accuracy class 1.6

- Overrange protection 100, 250, 400 or 600 bar (1500, 3000, 6000 or 10000 psi)

- Approvals

- IECEx

- ATEX

In addition to our absolute pressure gauge APCh (data sheet 3901), upon customer request we have checked the possibility to supply absolute pressure gauges with wetted parts made of Monel.

Yes, we can! We are looking forward to your request. Monel is considered to be very resistant to corrosion, many acids and especially fluorine F2. Even if you require another special material, please contact us so that we can coordinate the details of your application.

- Absolute pressure gauge

- Bayonet ring case stainless steel

- Nominal case size 100, 160 mm (4, 6")

- Accuracy class 1.6

- Pressure ranges

- from 0 – 25 mbar abs.

- to 0 – 400 mbar abs.

- Wetted parts Monel

- Process connection G 1⁄2 B

- Option flange connection

We have set ourselves the task of making our chemical seals with extension tube also applicable to those areas. The materials used are sour gas resistant according to NACE. We have solved the specifications regarding pressure resistance in accordance to the guidelines AD 2000, especially AD 2000 W2, by design and have reorganised our production. Moreover, we meet the special requirements on the weld seams (weld documentation, welding procedure tests) in accordance with DIN EN 15 613.

- AD 2000 W2 for austenitic and austenitic-ferritic steels

- AD 2000 W10 materials for low temperatures, e.g. −100 °C (−148 °F) PN 40

- NACE MR 0175 only material with acceptance test 3.1 is used

- Welding procedure according to DIN EN 15 613

- Pressure ranges 25 mbar to 40 bar

- Sour gas resistance according to NACE

- Pressure resistance according to AD 2000

- 6 weld seams less than the previous version, thus higher functionality

- No weld seam with additional material in the sealing area between extension tube and

flange - Weld seams not pressure-retaining

- Wetted parts made of titanium, Hastelloy and Monel, others upon request

- High surface finish – narrow tolerances

- Reduced delivery times

Especially for Arctic countries, where outside temperatures can drop to −60 °C (−76 °F), we have now developed a safety pressure gauge that is able to brave such temperatures…

Our RSChgG 160 – 3v does not only withstand extreme temperatures down to −60 °C (−76 °F), but also sandstorms, salt water or sea air. This pressure gauge can also be used in explosion hazardous areas.

- Accuracy class 1.0

- Nominal case size 160 mm (6")

- Pressure ranges −1 / 0 bar to 0 – 2500 bar

(−30" Hg / 0 psi to 0 – 35,000 psi) - Version bottom connection

- Safety category S3 according to DIN EN 837-1

- Permissible ambient temperature −60 °C to +60 °C

(−76 °F to +140 °F) - Process connection G 1⁄2 B

- Wetted parts stainless steel 316L

The PTC coating is also approved for use in the food industry.

PTC coatings enhance the mechanical properties of stainless steel chemical seals and increase the service life in case of difficult media. With the PTC coating on our High-Soft Membrane, no measurable additional errors occur. In-line seals and flange-type chemical seals with extension tube are also ideally suited for PTC coatings. PTC coatings of special materials upon request.

- Anti-adhesive

- Low friction coefficient

- High load capacity

- Exceptional durability

- Resistant to detergents

- Antistatic

- Extreme hardness

- Excellent thermal conductivity (99.8 %)

Highly corrosion-resistant solutions are required, for example for urea. We offer high quality chemical seals with extension tube, the flush welded diaphragm is here made of tantalum.

This high-quality special material is more corrosion-resistant than regular stainless steel and can therefore meet even more specific requirements. Due to the applied non-positive welding process, which connects extension tube and diaphragm, no surface roughness occurs. This allows for the use of the chemical seals also in pharmaceutical applications.

- Chemical seal stainless steel 316L (1.4404)

- Diaphragm tantalum flush welded with chemical seal

- Sealing face according to DIN EN 1092-1 or ASME

- Nominal width DN 50, 80, 100 or NPS 2", 3", 4"

- Nominal pressure 16 / 40

- Class 150 / 300

- Data sheet 7502

Bimetal thermometers TBi

thermowells make it complete

The safety and functionality of temperature measuring points is determined to a large extent by thermowells. They protect temperature measuring instruments against mechanical and chemical stress and enable the replacement of thermometers without interrupting the process.All standard models can be readjusted with an externally accessible adjusting mechanism. Individual dials with luminous colour, customer-specific markings and special prints optimise the instruments for their specific case of application.

We recommend combining bimetal thermometers with one of the thermowells from our large range, which are perfectly suitable for most applications.

- Materials

- case 304 (1.4301)

- temperature sensor 316Ti (1.4571)

- Degree of protection IP65 to IP67

- Liquid damped versions

- Indication accuracy class 1 according to EN 13 190,

optional: Grade A according to ASME B40.200 - Case diameters / nominal case sizes 2.5" (NCS 63),

3" (NCS 80), 4.5" (NCS 100), 5" (NCS 125), 6.5" (NCS 160) - Temperature ranges from −50 °C / −60 °F up to 460 °C / 850 °F

- Smallest measuring span 60 °C / 110 °F, e.g. −10 / +100 °F

- Scales in °C, °F, dual scales, e.g. °C / °F

other units upon request - Installation lengths from 2.5" (63 mm) up to 16" (406 mm)

optional: up to 35" (890 mm) - Stem diameters 6 mm, 8 mm, 10 mm (0.236", 0.315", 0.394"), optional: 6.35 mm (0.25")

Diesel exhaust thermometers TA

thermowells make it complete

The safety and functionality of temperature measuring points is determined to a large extent by thermowells. They protect temperature measuring instruments against mechanical and chemical stress and enable the replacement of thermometers without interrupting the process.- Materials

- case 304 (1.4301)

- temperature sensor 316Ti (1.4571)

- Degree of protection IP65

- Indication accuracy class 1 according to EN 13 190

- Case diameters / nominal case sizes 2.5" (NCS 63),

3" (NCS 80), 4.5" (NCS 100) - Standard temperature ranges

- 0 – 120 °C / 30 – 250 °F

- 50 – 650 °C / 110 – 1100 °F / 120 – 1200 °F

- Scales in °C, °F, dual scales, e.g. °C / °F and other units

- Dials from 500 °C / 930 °F full scale made of brushed aluminum with black scale

- Installation lengths from 6" (152 mm) up to 16" (406 mm)

optional: up to 35" (890 mm) - Stem diameters 12 mm, 13 mm (0.47", 0.512")

optional: 10 mm, 16 mm (0.394", 0.63")